Impressive numbers

60%

MES helps businesses to make decission more accurately by 60%

99%

MES helps businesses to control production progress more accurately by 99%

80%

80% of our cliens can optimize their cost after using MES

Manufacturing execution management module

Production capacity management

The system could help to manage and assess production capacity of every single production plant, group, and line.

Easy production ordering management and coordination

The system could integrate with ERP software and receive production orderings from the ERP layer, thereby allocating and coordinating such orderings to production plants and lines

Visual production scheduling with Gantt charts

The system enables optimal production scheduling for every single production plant and line with visual Gantt charts

Unified production procedure for all steps

Establish a unified standard production process for each product line, including: operating order, processing time, detailed production instructions, etc.

Real-time production data management

The system provides accurate data about the entire production process which is continuously monitored and transmitted to the central control system.

Easy to identify problems in production process

Visual information display by charts could help managers to quickly identify problems during production process.

Easier and more accurate production decission making

Production data analysis could provide suggestions for managers to make adjustment in production activities most effectively.

Warehouse management module

Inventory management by various information

The system allows to track information accurately about: storage location, storage method (shelves, boxes, pallets, trays, etc), batch information, item weight and dimensions for packaging

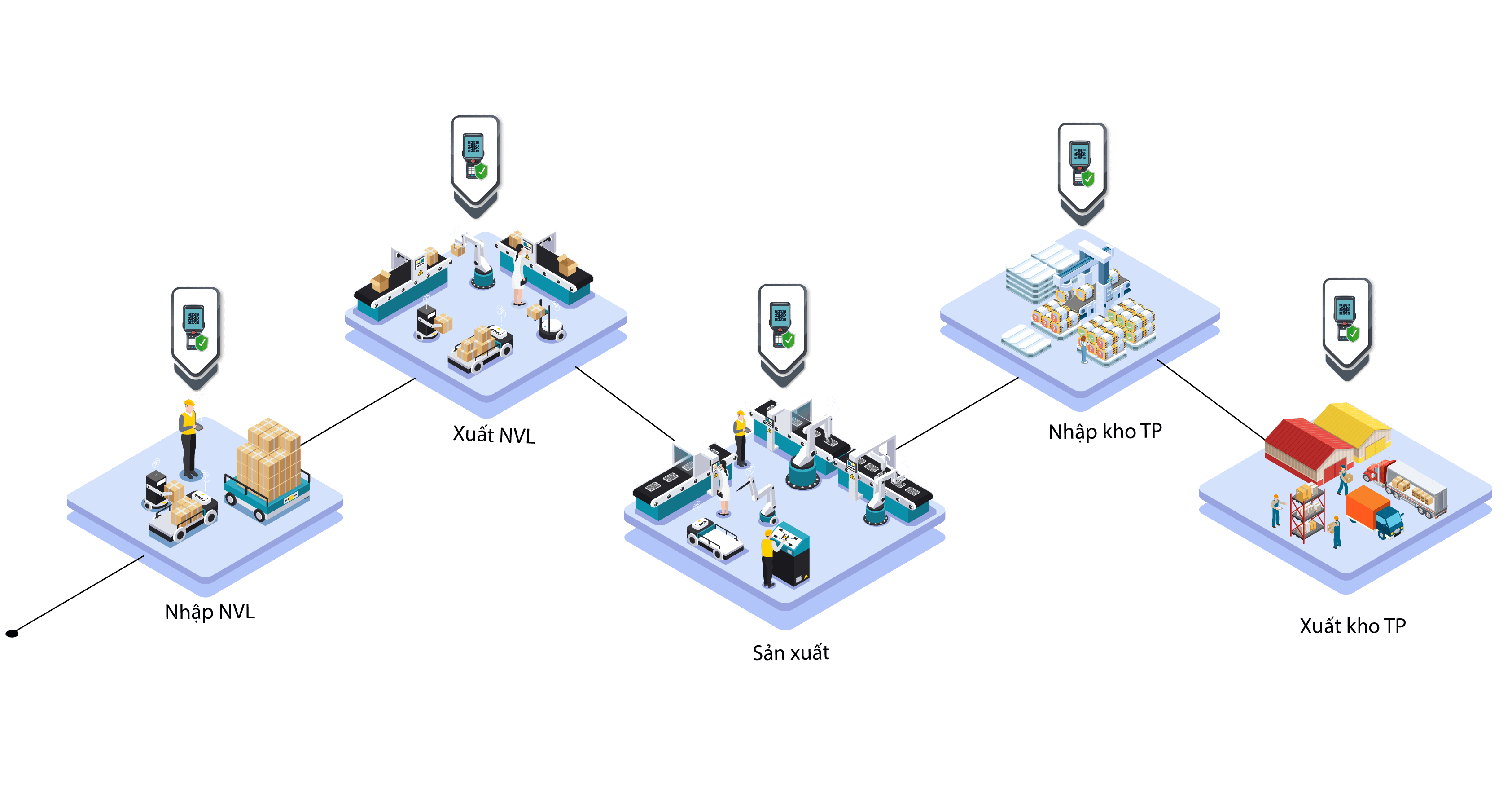

Precisely capture product flow in manufacturing

Data of product flow and work-in-progess (WIP) are displayed accurately in realtime

Stock-in/Stock-out/Stock-taking/Inventory check by Barcode/QC Code

The system allows to create and print product tagging automatically and enable stock-in/stock-out/inventory check by Barcode/QR Code, which helps to controll inventory activities in realtime.

Quality management module

Material and finished-product quality control

With our 3S MES, quality control is undertaken in every production stage, not in the finishing stage.

Error/Failure rate evaluation and cause analysis

The system enables to declare information of the quality control process, the quality indicators to be checked, the inspection rate and the causes of defects during stock-in and work-in-progress.

Error/Failure processing procedures establishment

The standard production procedure system allows to declare branching process in order for production work-in-progress defect processing.

Equipment management and maintenance management

Equipment digitization

Machinery details (technical specification, maintenance instructions, repairing tracking, etc) is digitized and extracted at any time

Realtime equipment control

The system helps to monitor the equipment operation status in realtime and report problems causing production disruptions.

Overall equipment efficiency (OEE) analysis and assessment

The system helps to collect information for overal equipment indicators and efficiency (OEE) analysis and assessment.

Set up equipment warning and troubleshooting procedures

The system allows users to set up warning methods and troubleshooting procedures when it comes to equipment failures. It also records the history of any equipment incident.

Set up maintenance and accessory replacing procedures

The system allows to set up procedures and scheduling of maintenance and accessory replacement automatically

Traceability module

Tracibility module of the 3S MES could help manufacturers to identify the components and production process of each finished-item quickly and correctly via QR Code/Barcode.

Typical features of the tracibility module: - Create records of tracibility for each product unit, which are detailed to serial number of each finished product/semi-finished product in each production stage. - Record all information of entire production process including: person-in-charge, running time of each production line/machinery. - Combined with the Warehouse Management Module to undertake tracibility by QRCode/Barcode. - Provide traceability for end users

Typical features of the tracibility module: - Create records of tracibility for each product unit, which are detailed to serial number of each finished product/semi-finished product in each production stage. - Record all information of entire production process including: person-in-charge, running time of each production line/machinery. - Combined with the Warehouse Management Module to undertake tracibility by QRCode/Barcode. - Provide traceability for end users

EN

EN